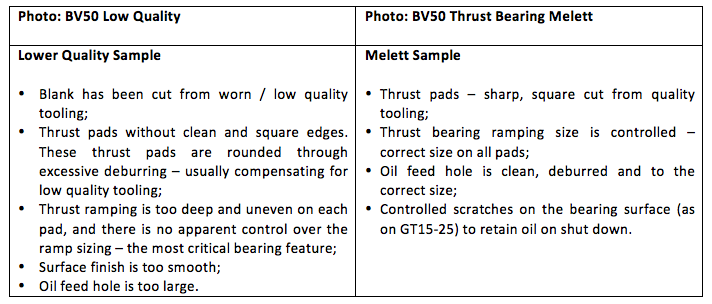

It is not uncommon for some turbocharger repairers to compare turbo products visually and assume that if the products look the same, then the products have been manufactured to the same standards. Here, we offer advice as to why visual comparison cannot be relied upon when considering the quality of products.

When new turbocharger components are under development, the cost of producing new tooling for that component can be very expensive. To aid development of components, manufacturers will often source parts from foundries that already have existing tooling for those components.

For such high-volume turbo products, foundries will develop their own tooling, enabling them to sell their castings to many different manufacturers. This enables the manufacturers to price their parts more competitively as they have saved in tooling costs.

So, what are the differences between these ‚quality‘ turbo products?

Even in cases where the same tooling is used, a foundry will produce castings to the specifications of their individual customers. These requirements can include completely different material specifications. Different post-casting processes (such as heat treatments or surface treatments) and different ‘pass/ fail’ quality criteria.

For example, quality manufacturers, including Melett, specify 100% high pressure oil/water gallery testing on all bearing housings; an extra cost which some lower cost manufacturers often prefer not to pay. Quality manufacturers may also specify strict dimensional controls on turbine wheel castings to ensure the balance quality of the end product. This means that the foundry typically incurs extra costs as it has a higher scrappage rate of substandard parts.

Another difference can be the tolerance levels requested on the design drawings. High tolerances on drawings mean more parts do not meet strict machining criteria. This again increases scrappage rates. For instance, for every 100 pieces produced, a manufacturer may have as many as 30 out of tolerance parts. This means that these 30 pieces will be scrapped and the production costs of these added to the overall price of the remaining 70 pieces.

To reduce such out of tolerance failures, some manufacturers will accept tolerance changes which reduce the machining quality required. In the above example but with lower tolerances, 85 items of the 100 pieces produced could meet the revised criteria, with only 15 pieces scrapped. Therefore, whilst the cost of the parts may have dropped, the component quality will also have reduced.

More than meets the eye

When comparing a high quality product with a lower cost alternative, it is risky to assume that they are equivalent parts, even if they look the same. As explained above, it is important to consider more than just the visual appearance of a component. If it appears to be cheap, it can be worth asking; ‘how do the manufacturers make this product so cheap?’ and ‘what corners may have been cut in terms of quality to achieve that low cost?’